In our first article in the “A Different Approach” series, SpaceWorks began exploring how the shifting space industry landscape has given way to a dramatic rise in vertical integration across the sector. Part I examined how constellation architectures are changing the calculus around when and when not to vertically integrate. Part II “A Day Late & A Component Short” picks up where this article left off, offering additional insight into the role of component suppliers in the new space paradigm, and how disconnects in purchasing preferences are impacting the decision to vertically integrate.

Part II: A Day Late & A Component Short

When talking about aerospace suppliers, it’s impossible to ignore Boeing’s 2012 “Partnering for Success” (PFS) initiative, nominally aimed at elevating the role of its supplier base[1]. The program, similar in nature to Airbus’ SCOPe+ plan, offered suppliers a simple choice: reduce costs, or else. This aggressive approach highlights the ongoing tension between suppliers and OEMs in the aerospace sector, with the former fighting to retain component margins as much as possible and the latter doing everything in their power to squeeze out price concessions[2].

Whether this infamous PFS strategy has ultimately helped Boeing and its supplier base is subject to much debate, however, one thing is clear: supplier performance is integral to the manufacturer’s profitability. In Boeing CEO Dennis Muilenburg’s own words, “I’ve witnessed firsthand the critical role suppliers – and especially the best ones – play in Boeing’s success” – a powerful statement coming from an executive who has taken a strong-arm approach to suppliers since he took the helm of the firm almost 4 years ago[3].

While Dennis Muilenburg wasn’t specifically speaking about satellite components (after all, satellites only account for ~3% of Boeing’s annual revenue), the sentiment remains: great suppliers make great supply chains[4]. When relationships are properly maintained, suppliers can provide reduced costs, greater efficiency, and steady pricing for their manufacturing partners, not to mention, critical market intelligence and subject matter expertise[5]. So why is that small satellite manufacturers are taking on vertically integrated strategies that eliminate the bulk of their supplier base altogether?

The Growing Disconnect

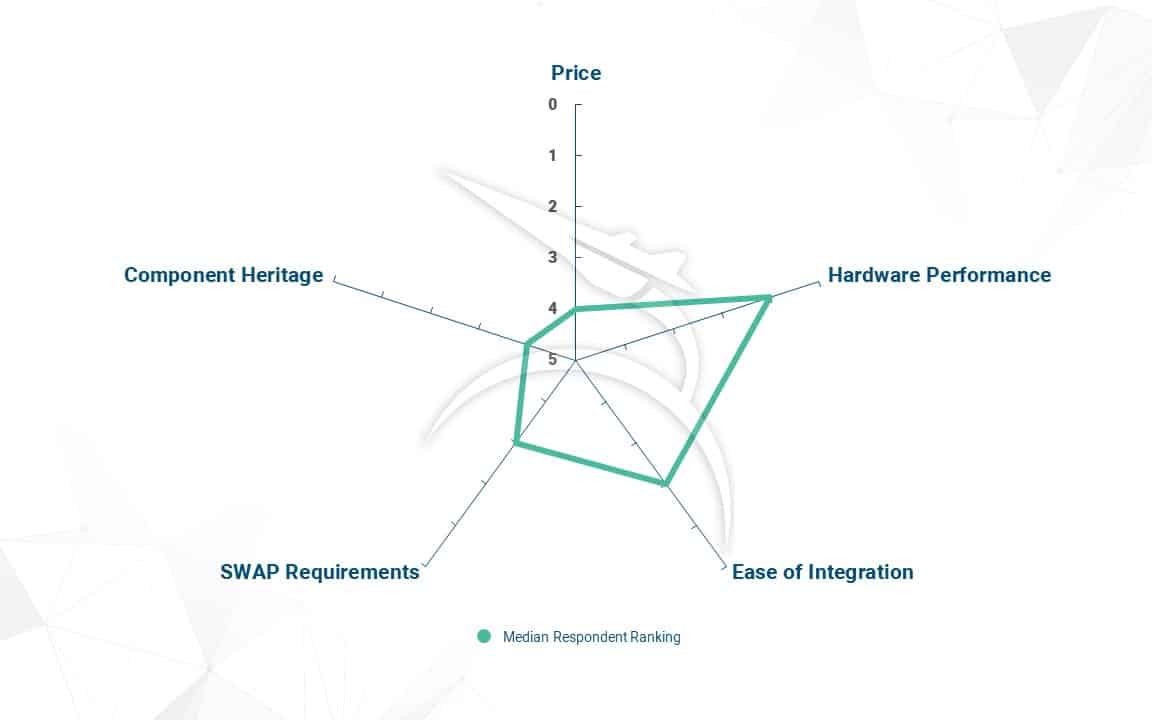

The small satellite revolution has brought unprecedented growth opportunities for component suppliers, but it has come with a cost. Driven by new customer types, capital sources, and management styles, the new generation of satellite manufacturers are operating with drastically different business models. In our discussions with industry executives, SpaceWorks found that these companies also have different purchasing philosophies (see Figure 1): small satellite manufacturers prioritize ease of integration, performance, and consistency over traditional component metrics, such as hardware heritage.

These shifting industry attitudes are more difficult to accommodate than one might imagine. The current vendor landscape is well suited to supporting the traditional spacecraft manufacturing base, but was never intended to rapidly produce constellations of 100s or even 1000s of satellites. A shockingly large number of aerospace components are still manufactured by hand. This process works fine when the average lead time is measured in months, but is less than ideal when those same lead times are measured in days. Throw in new manufacturer’s unwavering emphasis on cutting-edge hardware performance and a healthy dose of changing requirements and it becomes easy to see a growing disconnect between suppliers and manufacturers.

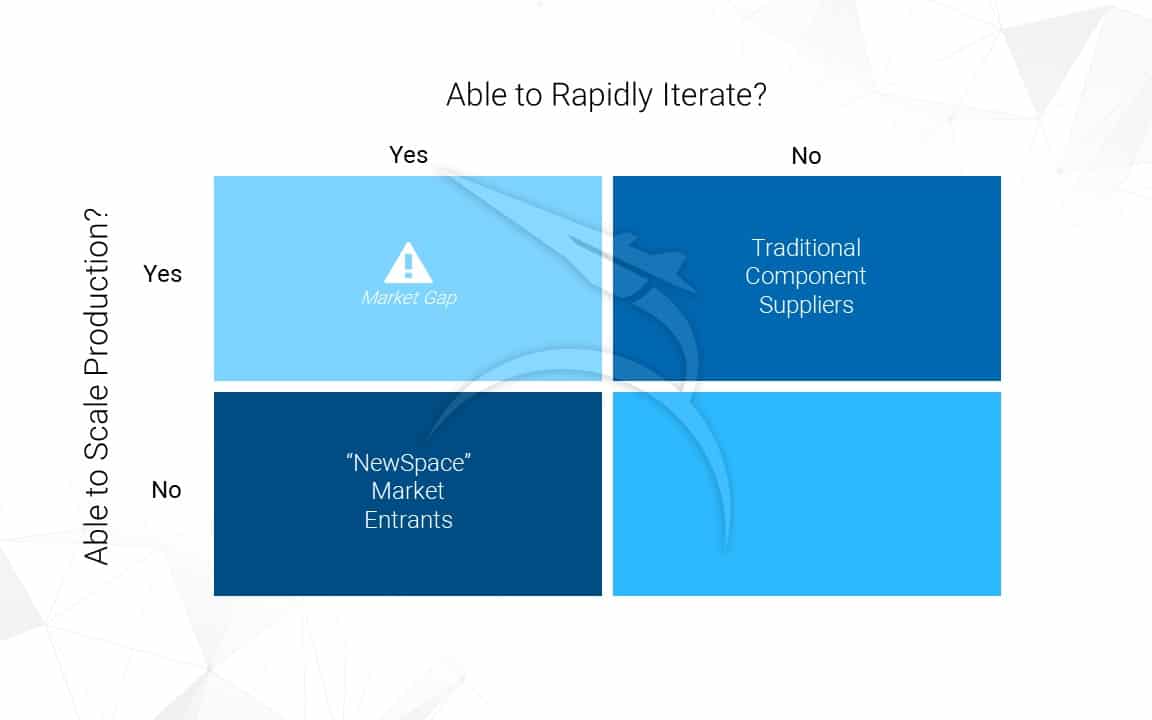

SpaceWorks research suggests that the root of this disconnect comes primarily from one of two sources: companies either can’t adapt to the iterative design approach, or can’t properly scale their processes for production. Manufacturers are often left with an impossible choice between rampant schedule delays or unreliable hardware. Figure 2 outlines this dichotomy between traditional and “NewSpace” component suppliers and highlights the critical market gap left in the marketplace.

In our discussions with satellite manufacturing executives, it seems that traditional component suppliers are better equipped to scale production processes, but lack the organizational persona to enable a highly iterative design approach. Conversely, newer market entrants are more comfortable with an iterative design approach, but have historically faced difficulties in scaling their production efforts. Either way, these struggles have led component suppliers to routinely under deliver when it comes to newer satellite constellations. The net result of this inability to adapt has been a dramatic reduction in component quality throughout the small satellite sector.

Across the industry, small satellites have reported failure rates of up to 50%, though this number is likely inflated by the inclusion of academic satellites and technology demonstration missions[6]. Still, SpaceWorks’ own research suggests a failure rate of 30% is in-line with early performance for commercial constellations. The cost of these failures adds up rapidly, especially when accounting for the compounding impact of launch costs.

One must refrain, though, from letting the vocal minority dictate opinions of the market overall. Certainly there have been a number of highly visible success stories from component suppliers who have adopted to this new world order and capitalized on the opportunities it presents[7]. It seems that therein may lie the most frustrating issue – many component vendors are unreliable about being unreliable.

A common complaint from manufacturers is that vendors that worked out brilliantly for technology demonstration missions can’t execute when it comes time for the full-scale constellation roll-out. Even when they are able to deliver, units from the same production facility may have wildly different performance and failure rates. Small satellite manufacturers haven’t helped the situation either. By sourcing components from a variety of vendors, many with limited hardware heritage, it makes it increasingly difficult to identify the responsible component when a failure does occur.

Whether this market disconnect is the result of an oversight, a conscious decision on the part of suppliers, or perhaps simply an outdated perception, is unclear. What is clear, is that in the eyes of many small satellite manufacturers (particularly those in the nanosatellite market), the current vendor landscape simply doesn’t meet their requirements.

Bridging the Gap

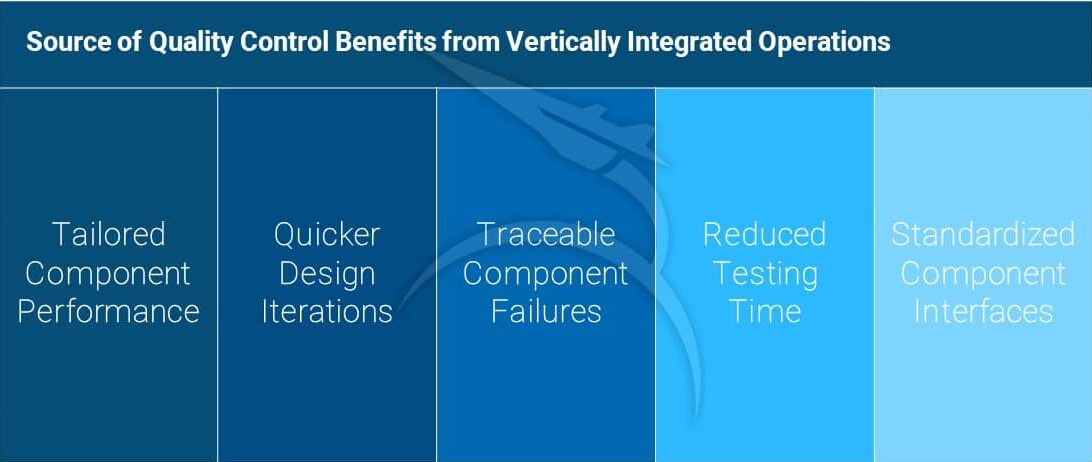

Fed up with the uncertainty, a number of manufacturers have begun following in the footsteps of NewSpace trailblazers like SpaceX and Blue Origin, vertically integrating to take component production in-house in an effort to improve component quality[8]. Compared to traditional manufacturing, this approach offers greater control over operations, increased oversight, streamlined component design, and the ability to implement design iterations faster – advantages traditional firms don’t get to experience. Figure 3 details the commonly cited sources of quality control improvements when using a vertically integrated approach.

The general idea from the point of view of the manufacturer is that removing unnecessary nodes in the supply chain will help eliminate integration disparities, enable faster design cycles, and provide overall improvements in component quality. Further, problematic components can be identified and replaced quickly, often in a matter of weeks[9]. Validation and verification time can also be minimized, allowing firms to rapidly introduce new features, without waiting on long component lead times.

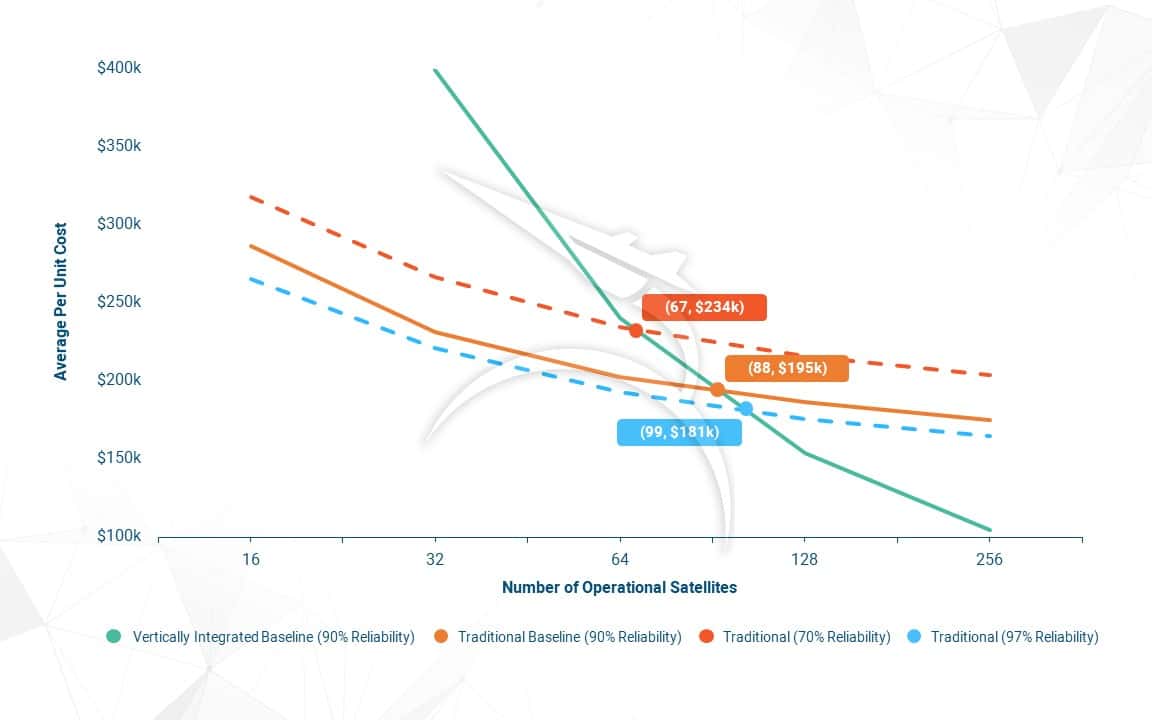

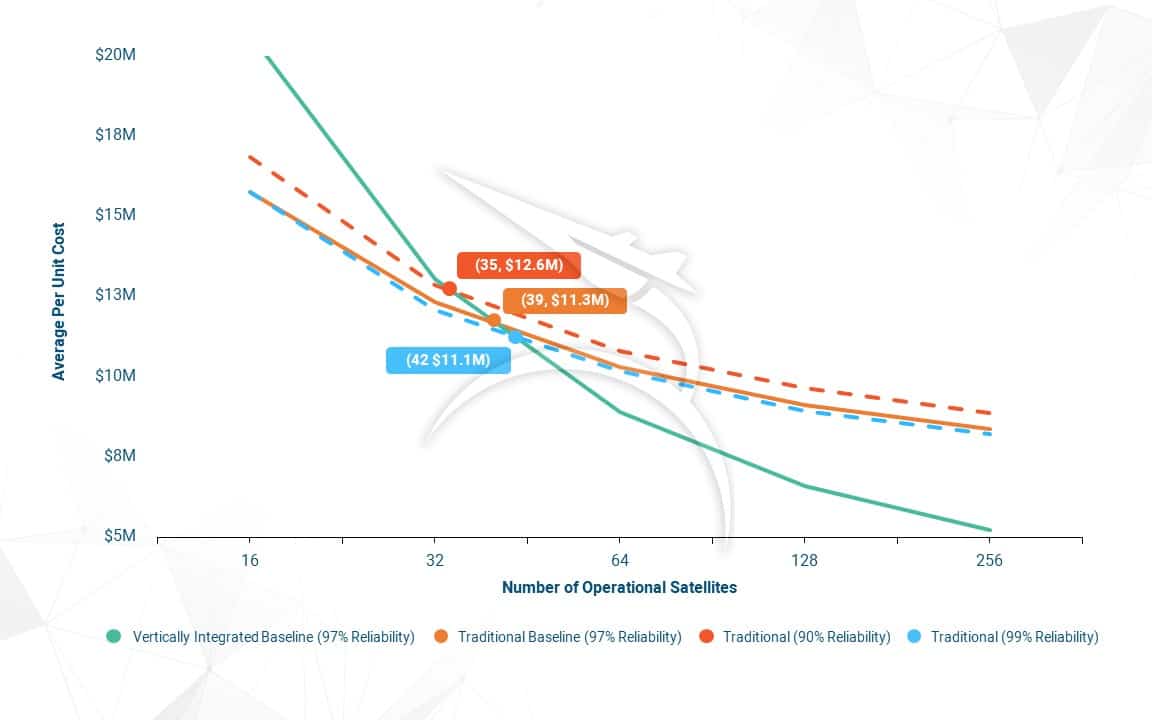

Of course, all of these benefits are only useful if they can manifest a bottom-line impact. The fastest design iterations in the world don’t help if component quality is not improved. It would seem that vertically integrating to improve quality control is only compelling if firms can capture these benefits while additionally reducing component failure rates. Assuming they can, however, the value proposition for vertically integrating looks quite appealing. Figures 4 & 5 explore the financial impact of improved quality control on the cost of two hypothetical satellite constellations.

As seen in Figure 4, SpaceWorks’ research suggests that improving quality control can yield significant cost savings. The historically low reliability rates present in the nanosatellite segment indicate that traditional component manufacturing processes may be immature, leaving significant room for improvement. If manufacturers are able to improve upon satellite reliability by adopting a vertically integrated approach, there could be substantial cost savings.

Within the 300 kg segment, historical reliability rates are already quite high – a reflection of more established suppliers and prototyping processes. Given the already high status-quo reliability rates present in this segment, the impact of vertically integrating to improve quality control is less significant. Understandably, marginal improvements in reliability yield marginal improvements in cost, and there is limited room to improve within this segment.

The results of SpaceWorks’ investigation into the hypothetical 300 kg constellation stand in stark contrast to that of the 3U. When status-quo reliability is low (as seen in the 3U constellation), vertical integration becomes more attractive; when status-quo reliability is high (as seen in the 300 kg constellation), such an approach offers little benefit. These findings shed additional insight into why constellations comprised of larger satellite sizes (such as Iridium, Telesat, etc.), may be less inclined to pursue vertically integrated approaches.

Perhaps the most important takeaway is that vertically integrating to resolve quality control issues is only advantageous if significant advancements can be made. Operators who rush to integrate out of frustration may find they face the same struggle to scale production as their former suppliers, only now they have the additional cost to go along with it. Alternative strategies, such as long-term partnerships or joint ventures, may offer a more attractive, less CAPEX intensive path forward for achieving the same results.

Conclusions

In this new world order, flexibility and speed are critical to success. Firms view their satellites as ever-evolving products, not one-time releases. Suppliers who embrace this iterative design approach are likely to find new revenue streams that didn’t even exist 10 years ago; those that can’t, or won’t adapt, will rapidly find themselves being cut out entirely.

Just because suppliers have struggled to keep pace with the changing demands of the small satellite segment does not mean they have no role in the ecosystem. The root of the current disconnect stems from an inability to scale production and iterate component designs with manufacturers, not a deep seeded incompatibility. Firm behavior is not static, and gaps do not stay present for long in the competitive marketplace. Even now, many suppliers are already devising ways to resolve these challenges and establish new partnerships for the future[10].

In discussions with industry, SpaceWorks has discovered that necessity, rather than desire, has driven much of the vertical integration behavior of small satellite manufacturers to-date. Integrated operators would prefer to focus on development of payloads and analytics engines, not component manufacturing – the goal is to sell insights, not spacecraft. Historically, suppliers simply haven’t able to meet their needs.

For those manufacturers who made the early plunge into integrated operations, many are beginning the see the financial benefits, both in terms of lower costs and differentiated component technology[11]. Given the venture-backed nature of many of these firms, one can see why they could not afford to wait for the supplier side of the market. As was the case for Boeing’s suppliers in 2012, the choice was effectively made for them: integrate, or else. Only time will tell if the early decision to vertically integrate will serve as the ultimate competitive advantage or ultimate company distraction.

What was necessary in the early days of the small satellite industry, however, may not be what is necessary now. In our discussions with industry, many of the largest manufacturers have indicated they would prefer to stand on someone else’s shoulders, if they could. Even now, several years into integration operations, they still express interest in returning to traditional procurement models, suggesting that vertical integration may not be as attractive as it would seem.